Optical Design

We are power users of Zemax OpticStudio, specializing in designing imaging systems for capture and display. Our team has highly specialized expertise in plastic optics for high volume applications as well as glass optics for high quality and environmentally demanding applications.

Optical analysis

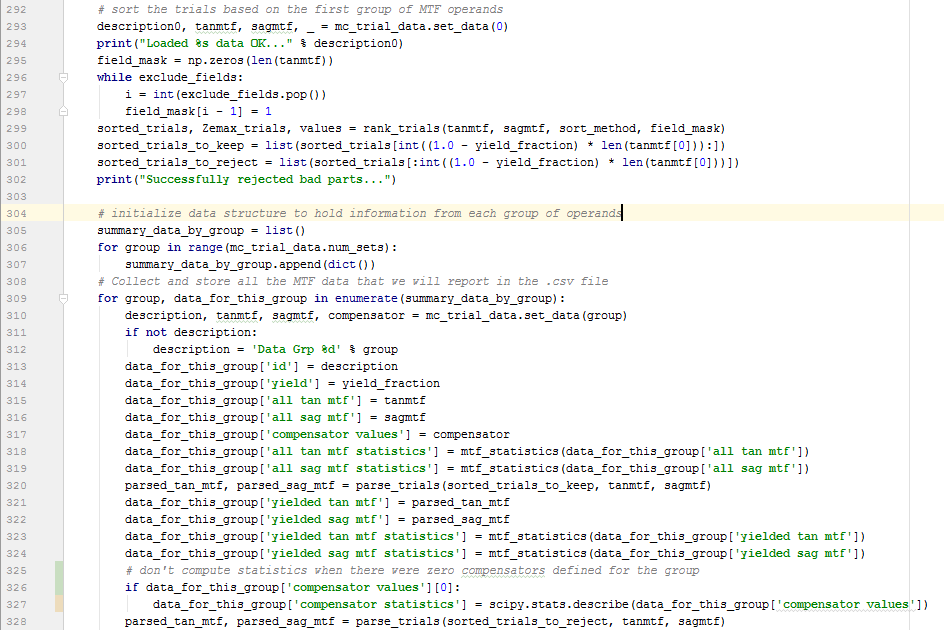

In addition to built-in Zemax tools, we’ve developed a great deal of proprietary Python code and macros for facilitating DfM (design for manufacturing) and for advanced analysis/visualization for tolerancing, yield prediction, stray light, and thermal simulation.

Opto-mechanical design

With SolidWorks as our go-to tool for mechanics, we have years of experience designing traditional lens mounts and focus assemblies, as well as complex systems, clever mechanisms, and full-blown industrial product designs.

Feasibility studies

We’re often called upon to help brainstorm concepts or to investigate potential design forms at the beginning of a project. This can be incredibly helpful to understand the design space, gauge feasibility for a new product, or set specifications prior to making a big investment in a product direction.

Supply chain support

We have long-running ties with many suppliers for optics, mechanics, and full camera modules. As an independent design group, we offer unbiased guidance on design form and supplier choice. We routinely facilitate both prototyping and transition to volume production for products we design.